In the pharmaceutical industry, steam and hot water are essential utilities for a wide range of critical processes: sterilization of equipment and product-contact surfaces, humidification in cleanrooms, heating of reactors and vessels, distillation of active pharmaceutical ingredients (APIs), drying of granules/tablets, and sanitization of pipelines. These applications demand high-purity steam (often “clean” or “pure” steam), precise temperature control, zero risk of contamination, and strict compliance with Good Manufacturing Practices (GMP), USP/EP pharmacopoeia standards, and cGMP regulations (e.g., FDA 21 CFR, EU GMP Annex 1, WHO guidelines).

For small-to-medium pharmaceutical facilities — such as API synthesis plants, formulation labs, biotech startups, contract manufacturing organizations (CMOs), research & development centers, or pilot-scale production lines — steam demand typically falls in the 0.5 to 2 tons per hour (TPH) range (equivalent to roughly 350–1,400 kg/h). In these scenarios, electric boilers (particularly electric steam boilers and electric thermal oil heaters) have become the preferred choice over traditional fuel-fired systems.

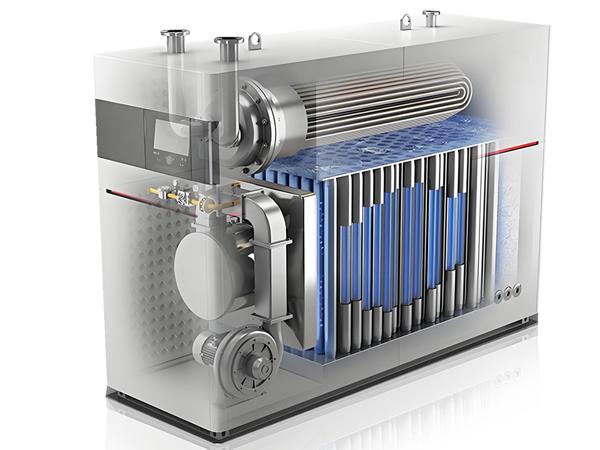

AIX Boiler, as China’s pioneering specialist in high-efficiency electric boilers (with near-100% energy conversion and true water-electricity separation), has supplied numerous compact electric units to pharmaceutical clients worldwide. This article explores why electric boilers excel in pharma applications at small capacities.

Why Electric Boilers Are Ideal for Pharmaceutical Processes

Pharmaceutical steam must meet rigorous purity requirements:

- Condensate of pure steam should comply with Water for Injection (WFI) specs (USP/EP): conductivity ≤1.3 µS/cm, bacterial endotoxins ≤0.25 EU/ml, no chemical additives.

- No non-condensable gases, dryness fraction ≥0.95, minimal superheat.

- Zero risk of boiler additives (amines, hydrazines) leaching into steam.

Electric boilers inherently satisfy these demands because:

- No combustion → zero on-site emissions (CO₂, NOx, SOx, particulates), eliminating exhaust stacks and flue gas treatment.

- No fuel → no risk of oil/gas leaks or burner-related contamination.

- Direct electric heating → clean, silent operation with precise control.

At 0.5–2 TPH, electric boilers offer unmatched advantages over gas/oil-fired or larger coal/biomass systems.

Key Advantages of Electric Boilers in Small-Capacity Pharma Applications

| Aspect | Electric Boiler (0.5–2 TPH) Advantage | Comparison to Gas/Oil-Fired Boilers (Small Scale) | Why It Matters in Pharma |

|---|---|---|---|

| Steam Purity & Cleanliness | Pure steam generation from treated feedwater; no additives; true water-electric separation (especially electromagnetic models) | Risk of carryover from combustion byproducts or boiler chemicals | Meets USP/EP WFI condensate specs; essential for direct-contact processes (e.g., sterilization, API distillation) |

| Zero On-Site Emissions | 100% electric → no NOx/SOx/particulates; supports carbon-neutral goals | Combustion emissions require scrubbers/after-treatment | Easier GMP compliance; ideal for urban labs or cleanroom-adjacent areas |

| Precise Temperature Control | PID/PLC control with ±1°C accuracy; rapid response (instant heat-up) | Burner modulation has hysteresis; slower response | Critical for jacketed reactors, lyophilizers, and drying ovens |

| Compact Footprint & Installation | Small modular units; no chimney/fuel tank; fits in clean zones or labs | Needs burner platform, exhaust stack, fuel storage | Space-limited facilities (R&D labs, pilot plants, CMOs) |

| Silent & Vibration-Free Operation | No burner/combustion noise/vibration | Noisy burners and fans | Suitable for cleanrooms and sensitive analytical labs |

| Low Maintenance & High Reliability | No burner/exhaust cleaning; minimal scaling (magnetic anti-scaling in advanced models); 15–20+ year lifespan | Frequent burner tuning, soot cleaning, fuel quality issues | Reduced downtime; easier validation/IQ/OQ/PQ |

| Energy Efficiency & Cost Predictability | Near-100% conversion efficiency; off-peak electricity tariffs possible | 85–92% efficiency; fuel price volatility | Lower OPEX in regions with stable/renewable electricity |

| Safety & GMP Compliance | No explosion/fire risk; easy integration with SCADA/PLC for automated monitoring | Combustion hazards; more complex safety interlocks | Aligns with risk-based GMP; simpler qualification |

Typical Small-Capacity Applications in Pharma (0.5–2 TPH)

- Sterilization & Autoclaving Pure steam for porous/hard-good autoclaves, SIP (Sterilize-in-Place) of vessels/piping, and terminal sterilization of small batches. Electric boilers provide consistent dry steam with low non-condensables.

- API Synthesis & Extraction Heating of reactors, evaporators, and distillators for solvent recovery or concentration. Precise ramp/soak profiles prevent degradation of heat-sensitive compounds.

- Granulation, Drying & Coating Fluid bed dryers, tray dryers, and pan coaters require stable hot air/steam. Electric units deliver clean, dry heat without combustion byproducts.

- Cleanroom Humidification & HVAC Support Steam injection for humidity control in sterile areas; electric boilers ensure no particulates or odors.

- Pilot & R&D Labs Small-scale formulation testing, stability chambers, and biotech fermenters benefit from compact, plug-and-play electric systems.

- Sanitization & Cleaning Hot water/steam for CIP/SIP of tanks, fillers, and lyophilizers.

Real-World Benefits Reported by Pharma Users

Many small-to-mid pharma facilities (especially in China, India, Southeast Asia, and emerging biotech hubs) report:

- Defect/contamination reduction of 30–60% due to purer steam.

- Energy cost savings of 15–40% with off-peak power and high efficiency.

- Faster qualification/validation — electric systems simplify IQ/OQ/PQ protocols.

- Compliance edge — zero emissions help secure environmental permits and ESG certifications.

AIX Boiler’s Edge in Small Pharma Electric Boilers

AIX Boiler offers a full range of electric steam boilers (0.5–2 TPH) and electromagnetic models, featuring:

- Near-100% efficiency with true separation.

- Stainless steel construction (316L options) for clean steam.

- Advanced controls for GMP-compliant data logging.

- Compact designs fitting clean zones.

- Proven installations in API, formulation, and biotech plants.

For small-capacity pharma needs, electric boilers deliver clean, precise, reliable heat without the drawbacks of combustion systems.

Ready to electrify your pharmaceutical process? Contact AIX Boiler for a free consultation, heat load assessment, or customized proposal:

- Email: [email protected]

- Website: https://www.aixboiler.com

- WhatsApp/WeChat: +86 135 9805 9888

- Global 24/7 Support: We’re here to support your GMP-compliant heating needs.

Choose AIX Boiler — clean, efficient electric solutions for pharmaceutical excellence.