In the field of industrial heating, the hot air boiler (also known as hot air furnace, hot air generator, or indirect hot air heater) stands out as a highly efficient and versatile solution for processes that require direct, clean, high-temperature air. By passing ambient or recirculated air through a heat exchanger, the system delivers hot air at temperatures typically ranging from 80–500°C (and up to 800°C in specialized designs) — without any combustion byproducts, moisture, or contaminants entering the process stream.

Compared to steam boilers, thermal oil systems, or direct-fired burners, hot air boilers offer unique advantages that make them the preferred choice in many drying, curing, baking, and preheating applications. Below are the key reasons why more and more enterprises are choosing hot air boilers.

1. Direct Contact Heating — Highest Heat Transfer Efficiency

Hot air boilers supply hot air that comes directly into contact with the material, combining convection and radiation heat transfer in a single step.

Typical comparison:

- Steam boiler → steam → heat exchanger → hot air → material (multi-stage heat transfer, high losses)

- Thermal oil boiler → thermal oil → heat exchanger → hot air → material (also multi-stage)

- Hot air boiler → combustion/electric heating → heat exchanger → direct hot air → material (single-stage transfer)

Real-world benefit: In high-airflow, low-temperature-difference processes — such as grain drying, wood lumber drying, feed pellet drying, fruit & vegetable dehydration, or tea/spice roasting — hot air boilers achieve overall thermal efficiencies of 80–92%, often 10–25% higher than steam-based systems. This translates directly into lower fuel or electricity consumption.

2. Clean Hot Air — No Combustion Pollutants Reach the Product

Thanks to the indirect heating design, flue gases from combustion (or exhaust from electric heating) are completely separated from the process air. The output hot air is free of NOx, SOx, CO, soot, or water vapor.

This is critically important in the following industries:

- Food processing (tea, medicinal herbs, spices, nuts, dehydrated fruits/vegetables) — meets strict food safety and hygiene standards.

- Pharmaceuticals & chemicals (API drying, powder coating, pigment drying) — ensures no contamination of sensitive materials.

- Wood products (lumber, plywood, MDF, particleboard, pellets) — prevents surface discoloration or chemical residues.

- Nonwovens & textiles (fabric heat-setting, curing of coatings) — avoids yellowing or odor pickup.

3. Flexible Temperature & Airflow Control

Hot air boilers allow precise adjustment of outlet temperature, airflow volume, and humidity (via fresh air/recirculation ratio). Many models support:

- Multi-stage temperature programming

- Variable frequency fans for airflow modulation

- PLC + touch screen control with remote monitoring

This level of control is essential for processes requiring different temperature profiles — such as slow ramp-up in API drying, rapid flash drying in snacks, or uniform curing in coatings.

4. Wide Fuel Flexibility & Energy Cost Options

AIX Boiler hot air boilers support multiple fuel types:

- Coal / biomass (wood chips, pellets, rice husk, straw)

- Oil / natural gas / LPG

- Electricity (resistance or electromagnetic heating)

This allows users to select the most economical or sustainable option based on local energy prices, availability, and environmental regulations. In regions with low-cost biomass or off-peak electricity, operating costs can be significantly lower than steam or direct-fired systems.

5. Compact Design, Easy Installation & Low Maintenance

- No need for high-pressure vessels, water treatment, condensate return, or large chimneys.

- Modular skid-mounted options for quick setup and relocation.

- Fewer auxiliary systems (no deaerators, no steam traps, no fuel pumps in electric models).

- Maintenance is mainly limited to cleaning the heat exchanger tubes and checking fans/burners — far simpler than steam boiler blowdowns or thermal oil system flushing.

6. Environmentally Friendly & Future-Proof

- Indirect heating reduces on-site emissions when using clean fuels or electricity.

- Electric hot air boilers produce zero combustion emissions at the point of use, supporting carbon-neutral goals and easier permitting in urban or regulated areas.

- Biomass-fired models qualify as renewable energy in many jurisdictions, helping companies meet ESG targets.

Real-World Industries That Choose Hot Air Boilers

- Grain, feed & agricultural products — drying corn, soybeans, alfalfa, forage, seeds

- Food & beverage — drying fruits/vegetables, roasting nuts/coffee/tea, puffing snacks

- Wood & panel products — lumber kiln drying, pellet production, plywood/MDF pre-drying

- Pharmaceutical & chemical — API/intermediate drying, fertilizer granules, catalyst regeneration

- Textile & nonwovens — heat-setting, curing, drying after dyeing

- Building materials — gypsum board drying, ceramic glaze drying, sand/aggregate preheating

- Emerging applications — lithium battery electrode drying, sludge dewatering, tobacco curing

Conclusion

Hot air boilers are chosen because they deliver the cleanest, most efficient, and most controllable form of direct heating for drying and thermal processes. They eliminate unnecessary intermediate steps (steam or oil loops), reduce energy waste, ensure product purity, and adapt easily to different fuels and regulations.

Whether you need high-volume low-temperature drying or precise high-temperature curing, a hot air boiler often provides the best balance of performance, cost, and reliability.

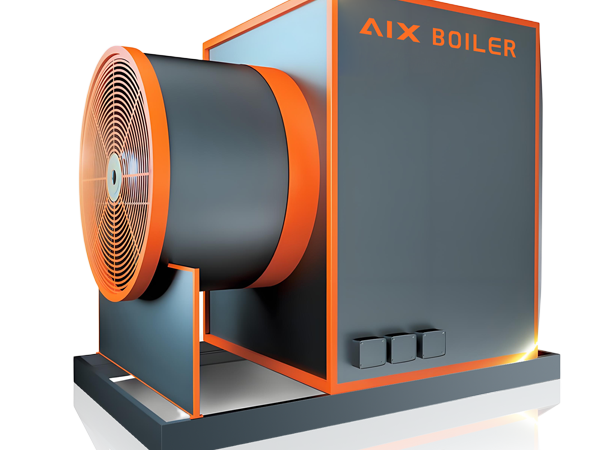

AIX Boiler manufactures a complete range of hot air boilers — coal/biomass, oil/gas, and fully electric models — backed by 45+ years of experience, A-grade certification, and proven installations worldwide.

Ready to explore how a hot air boiler can optimize your process? Contact the AIX Boiler team today:

- Email: [email protected]

- Website: https://www.aixboiler.com

- WhatsApp/WeChat: +86 135 9805 9888

- Global 24/7 Support: We’re here for heat load calculations, fuel analysis, and customized proposals.

Choose hot air boilers — clean, efficient, and process-optimized heating from AIX Boiler.