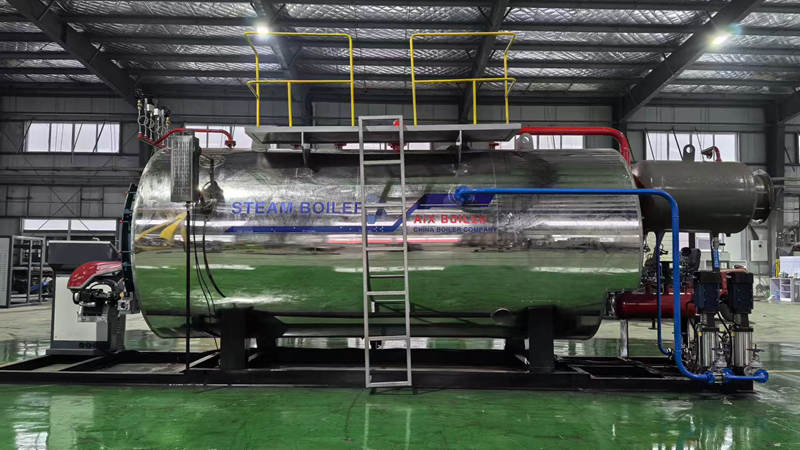

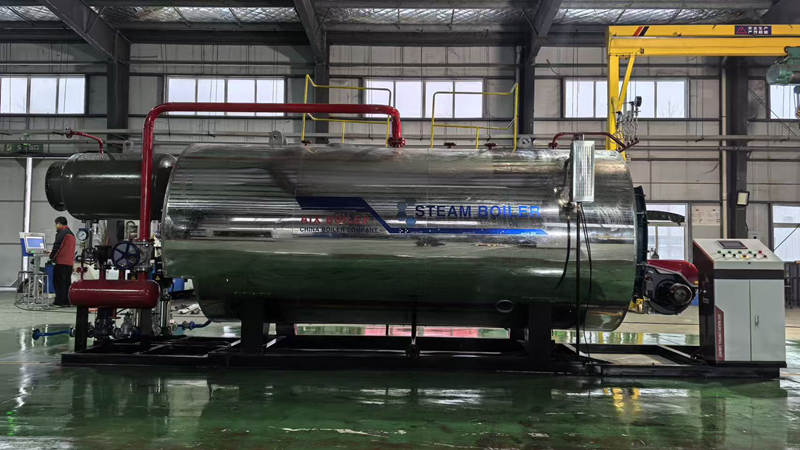

In 2025, AIX Boiler supplied a 2 TPH LDR series electric steam boiler to a medium-sized chemical manufacturing plant located in Callao, near Lima, Peru. The client specializes in producing industrial solvents, adhesives, and water-treatment chemicals, requiring high-purity, stable steam for reactor heating, distillation, evaporation, and sterilization processes in a GMP-like clean production environment.

Key Project Details

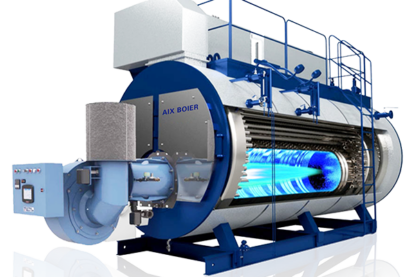

- Boiler Model: LDR2-0.7 (electric resistance steam boiler)

- Rated Evaporation: 2 tons/hour (saturated steam)

- Working Pressure: 0.7 MPa

- Steam Temperature: 170°C

- Power Supply: 380V/50Hz industrial grid

- Applications:

- Jacket heating for chemical reactors and mixing tanks

- Steam distillation and solvent recovery

- Sterilization of equipment and pipelines (SIP)

- Humidification and process heating in clean zones

Why the Client Chose AIX Boiler

- Zero on-site emissions and no combustion risk — perfect for indoor chemical production with strict safety and air quality requirements in Peru

- Near-100% energy conversion efficiency, stable steam output, and precise ±1°C temperature control, ensuring consistent product quality

- Compact, fully automatic design with PLC control, over-temperature/low-water protection, and easy integration into existing facilities

- High-purity steam from treated feedwater, no additives or carryover risks — compliant with chemical industry hygiene standards

- Reliable long-life resistance heating elements and low maintenance, ideal for Peru’s humid coastal climate

Project Timeline

- Order confirmation: Q1 2025

- Manufacturing & testing: 45 days at AIX Boiler factory

- Sea freight to Callao port: Q2 2025

- Installation & commissioning: Q3 2025

- Full commercial operation: August 2025

Client Outcome The boiler has delivered clean, reliable steam with zero downtime since startup, eliminated fuel logistics and exhaust treatment costs, reduced energy expenses through high efficiency and off-peak tariffs, and ensured full compliance with Peru’s environmental and industrial safety regulations. This project strengthens AIX Boiler’s presence in Latin America’s chemical sector with sustainable electric heating solutions.

For similar electric steam boiler projects in chemical or pharmaceutical industries, contact AIX Boiler: Email: [email protected] WhatsApp: +86 15188365066 / +86 13037600603 Website: https://www.aixboiler.com