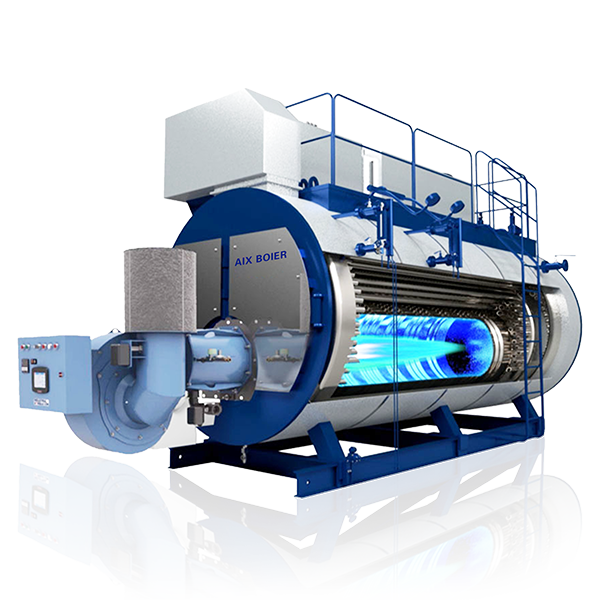

Product Description

AIXBOILER, a leading A-GRADE boiler manufacturer in China with over 45 years of expertise since 1978, offers advanced condensing oil/gas fired boilers. These units capture latent heat from flue gas condensation, achieving thermal efficiencies over 100% (based on lower heating value), significantly reducing fuel consumption and emissions compared to conventional boilers.

Manufactured in our state-of-the-art facility in Taikang Industrial Park, Zhoukou City, Henan Province—the “Hometown of Boilers”—AIXBOILER condensing boilers feature stainless steel or aluminum heat exchangers for corrosion resistance, integrated economizers/condensers, and low-NOx burners. Available in steam or hot water configurations, they support natural gas, LPG, diesel, and dual fuels.

Ideal for energy-intensive industries like food processing, chemicals, textiles, pharmaceuticals, and district heating, these boilers provide substantial cost savings and environmental benefits. AIXBOILER condensing technology supports global sustainability goals, with units exported to over 80 countries.

Key Features and Benefits

- Ultra-High Efficiency → Up to 108% by recovering latent heat.

- Low Emissions → NOx <30 mg/Nm³ with advanced combustion.

- Corrosion Resistance → Durable condensing heat exchangers.

- Fuel Savings → 10-20% reduction vs. non-condensing models.

- Compact Integration → Built-in condenser for easy installation.

- Intelligent Control → PLC automation for optimal operation.

Technical Parameters

The table summarizes typical specifications for AIXBOILER condensing oil/gas fired boilers (steam/hot water; custom available):

| Parameter | Specification Range | Notes / Standard Models |

|---|---|---|

| Rated Steam Capacity | 1 t/h – 40 t/h | Common: 2 – 20 t/h |

| Rated Thermal Power (Hot Water) | 0.7 MW – 28 MW | For heating applications |

| Rated Working Pressure | 0.7 MPa – 2.5 MPa | Low to medium pressure |

| Thermal Efficiency | 102% – 108% (LHV basis) | With full condensation |

| Fuel Type | Natural Gas, LPG, Diesel, Light/Heavy Oil | Dual-fuel options |

| Condenser Material | Stainless Steel 316L / ND Steel | Acid dew point resistance |

| Burner Brand | Riello, Baltur, Weishaupt | Ultra-low NOx |

| Control System | PLC + Touch Screen | Modulating control for efficiency |

| Flue Gas Temperature | 50°C – 80°C (outlet) | Maximizes condensation |

| Dimensions (approx.) | Varies with capacity | Horizontal packaged |

| Weight (dry) | 8 tons – 60 tons | Including condenser |

| Emissions | NOx ≤ 30 mg/Nm³, CO ≤ 50 mg/Nm³ | Eco-friendly compliance |

These parameters deliver superior energy recovery and performance.

Views of condensing heat exchangers and sectional designs:

Design and Construction Standards

AIXBOILER condensing boilers meet:

- Primary Standards: GB/T 16507 (China), optional ASME, PED 2014/68/EU, CE

- Materials: Corrosion-resistant alloys for condensing section

- Welding & Inspection: 100% NDT, hydrostatic testing

- Accessories: Integrated condenser, drain system, economizer

Optimized for maximum latent heat recovery and longevity.

Applications

AIXBOILER condensing boilers are ideal for:

- Industrial steam/hot water in energy-saving projects

- Food & beverage processing

- Chemical and pharmaceutical plants

- Textile dyeing

- District heating systems

- Greenhouse and building HVAC

They reduce operational costs while meeting strict emission regulations.

Quality Assurance and Testing

Each boiler undergoes:

- Efficiency and condensation performance tests

- Emission verification

- Full NDT and third-party inspection (TUV, SGS, BV available)

- Factory commissioning

Ensuring reliable, high-efficiency operation.

Why Choose AIXBOILER?

With family heritage since 1978, government designation in 2025, and over 60 senior engineers, AIXBOILER leads in condensing technology. We provide complete solutions: custom design, manufacturing, professional installation, and 24/7 maintenance for sustainable, cost-effective heating worldwide.

Specifications

Steam Boiler

| Model | Rated evaporation

capacity (t/h) |

Rated steam

pressure (Mpa) |

Thermal efficiency

(%) |

Fuel consumption | Overall dimension

(m) |

Weight

(t) |

Body Heating

Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) | Overall Dimension

Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

| Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3

2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

- Hot Tag