Description

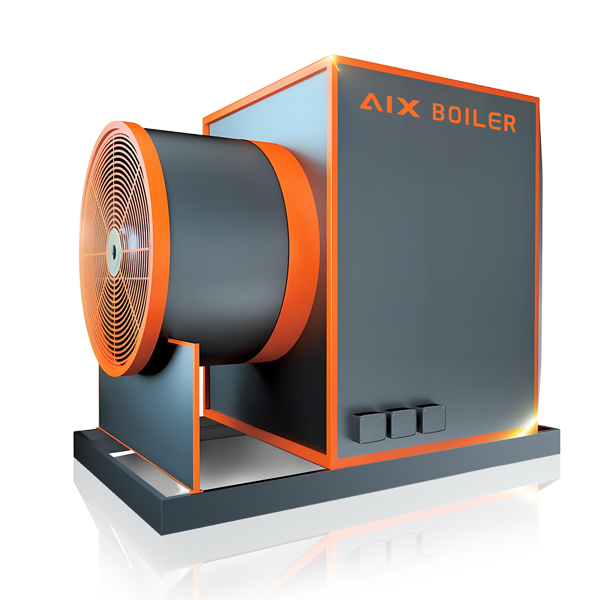

AIXBOILER, China’s No.1 ranked electric boiler manufacturer, offers advanced electric hot air boilers (hot air generators/furnaces) in three types: Resistance Heating, Electrode (Electromagnetic), and Semiconductor Heating. These provide clean, zero-emission hot air up to 21,600 kW for industrial drying and heating.

Inquiry Now

Product Description

AIXBOILER leads China as the top-ranked electric boiler manufacturer with over 45 years of expertise since 1978. Our electric hot air boilers (also known as electric hot air generators or furnaces) produce high-temperature clean air directly via electric heating, eliminating combustion for zero direct emissions, no pollution, and precise control—ideal for sensitive environments like food drying, pharmaceuticals, and textiles.

Leveraging our dedicated electric boiler factory since 2020, AIXBOILER supplies advanced units to major clients including CNPC, Sinopec, and CNNC. Manufactured in Taikang Industrial Park, Zhoukou City, Henan Province, these systems reach efficiencies up to 99.5% and power up to 21,600 kW, delivering hot air for processes requiring uniform, contaminant-free heating.

We offer three innovative heating technologies:

- Resistance Heating Type: Open or finned coils for reliable air heating.

- Electrode (Electromagnetic) Type: High-power indirect heating for large-volume air flows.

- Semiconductor Heating Type: PTC elements for safe, self-regulating high-temperature air.

Perfect for industrial drying, curing, preheating, and space heating in eco-restricted zones.

Key Features and Benefits

- China’s Leading Electric Boiler → No.1 in technology, capacity, and reliability.

- Zero Emissions & Clean → No exhaust, suitable for cleanrooms.

- Up to 21,600 kW Power → Massive airflow and temperature capabilities.

- Near 100% Efficiency → Energy-saving with low operating costs.

- Flexible Types → Resistance for standard, Electrode for high-volume, Semiconductor for safety.

Technical Parameters

The table compares specifications across AIXBOILER’s three electric hot air boiler types (custom up to 21,600 kW):

| Parameter | Resistance Heating Type | Electrode (Electromagnetic) Type | Semiconductor Heating Type |

|---|---|---|---|

| Rated Power | 50 kW – 5,000 kW | 500 kW – 21,600 kW | 100 kW – 10,000 kW |

| Hot Air Output | Up to 50,000 m³/h | Up to 200,000 m³/h | Up to 100,000 m³/h |

| Outlet Air Temperature | 50°C – 600°C | 100°C – 800°C | 60°C – 500°C (self-regulating) |

| Efficiency | 95 – 99% | 98 – 99.5% | 97 – 99% (auto-limiting) |

| Heating Method | Electric coils/fins in airflow | Electromagnetic induction or electrode | PTC ceramic/semiconductor elements |

| Air Flow Control | Variable fan speed | High-volume duct integration | Precise modular control |

| Startup Time | 5-20 minutes | 10-30 minutes | 5-15 minutes |

| Best For | Drying, curing, general heating | Large-scale industrial air processes | High-safety, variable temperature apps |

| Power Supply | 380V-690V | High-voltage 6-10 kV | 380V-690V |

| Maintenance | Coil cleaning/replacement | Minimal electrode access | Very low (self-protecting) |

These configurations ensure optimal performance for diverse industrial hot air needs.

Here are examples of high-power duct and hot air generator systems (electrode/electromagnetic style):

Design and Construction Standards

All AIXBOILER electric hot air boilers meet GB/T standards (China), with optional CE/PED. Features include insulated ducts, high-temperature fans, advanced PLC controls, and multi-safety interlocks (overheat, airflow failure).

Types in Detail

Resistance Heating Type Air passes over heated coils for direct, efficient transfer—versatile for most applications.

Electrode (Electromagnetic) Type Indirect electromagnetic fields heat air streams powerfully—suited for ultra-high volume and temperature.

Semiconductor Heating Type PTC elements provide inherent overheat protection and uniform heating—ideal for precision and safety.

Examples of advanced semiconductor/PTC hot air heating elements and systems:

Applications

AIXBOILER’s three types excel in:

- Resistance: Food drying, painting curing

- Electrode: Large factory preheating, chemical processes

- Semiconductor: Pharmaceutical drying, electronics

Delivering clean, controllable hot air globally.

Quality Assurance and Testing

Comprehensive airflow, temperature, and electrical testing with third-party certification ensure No.1 performance.

Why Choose AIXBOILER?

As China’s top-ranked electric boiler manufacturer with 2025 government designation, AIXBOILER pioneers high-capacity (up to 21,600 kW) clean air solutions. Our 60+ senior engineers provide full support: custom design, installation, and 24/7 maintenance.