Description

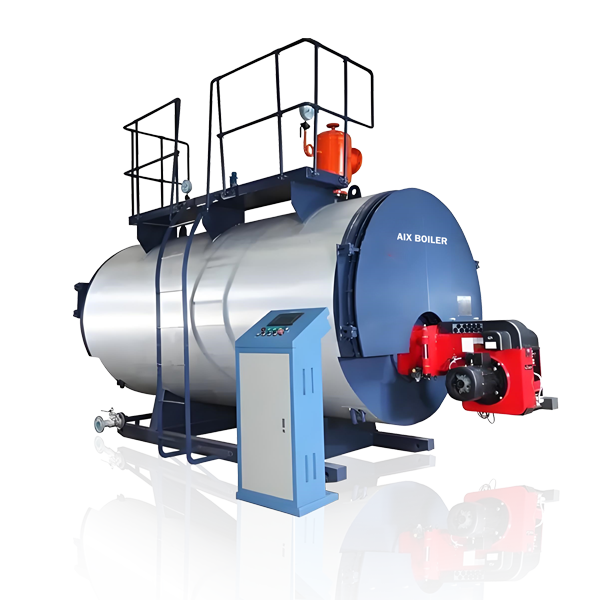

The WNS Series Oil/Gas Fired Steam Boiler is a horizontal, three-pass, wet-back fire-tube boiler that combusts oil or gas to produce steam for industrial applications. Manufactured by AIX Boiler, a Chinese A-grade producer since 1976, these boilers feature high thermal efficiency (up to 98%) with advanced burners, economizers, and corrugated furnaces, reducing fuel costs. Their compact, fully automatic design ensures easy installation, operation, and low NOx emissions, meeting environmental standards. Ideal for industries like textiles, food processing, and chemicals, AIX WNS boilers offer durability, safety with explosion-proof features, and low maintenance, making them a reliable, eco-friendly heating solution.

Inquiry Now

Product Description

AIXBOILER, a leading A-GRADE boiler manufacturer in China with over 45 years of expertise since 1978, offers the WNS series horizontal internal combustion oil/gas fired steam boilers. This fully automatic, three-pass fire tube wet-back design ensures high thermal efficiency, low NOx emissions, and reliable operation for a wide range of fuels including natural gas, LPG, diesel, heavy oil, and dual-fuel options.

Manufactured in our advanced facility in Taikang Industrial Park, Zhoukou City, Henan Province—the “Hometown of Boilers”—the WNS series incorporates corrugated furnace for enhanced strength, threaded smoke tubes for improved heat transfer, and imported burners (e.g., Weishaupt, Riello, Baltur) for complete combustion. These boilers are widely used in food processing, textiles, chemicals, pharmaceuticals, paper mills, and laundries, providing saturated steam with quick startup and stable performance.

Committed to eco-friendliness, AIXBOILER WNS boilers feature low-emission technology and optional economizers/condensers for efficiencies over 98%, supporting sustainable industrial operations exported to over 80 countries.

Key Features and Benefits

- High Efficiency → Three-pass design with large combustion chamber and heat transfer surfaces.

- Low Emissions → Advanced burners and optional FGR for ultra-low NOx.

- Safety & Automation → PLC control, multiple interlocks, and remote monitoring.

- Compact & Quick Installation → Packaged design with skid-mounted accessories.

- Fuel Flexibility → Oil, gas, or dual-fuel with easy switching.

- Durability → Wet-back structure prevents refractory damage and extends lifespan.

Technical Parameters

The following table summarizes typical specifications for AIXBOILER WNS oil/gas fired steam boilers (custom ranges available):

| Parameter | Specification Range | Notes / Standard Models |

|---|---|---|

| Rated Steam Capacity | 0.5 t/h – 40 t/h | Common: 1 – 20 t/h |

| Rated Working Pressure | 0.7 MPa – 2.5 MPa (7 – 25 bar) | Low to medium pressure options |

| Saturated Steam Temperature | 170°C – 204°C | Depending on pressure |

| Thermal Efficiency | 92% – 98% (up to 104% with condenser) | With economizer and advanced combustion |

| Fuel Type | Natural Gas, LPG, Diesel, Heavy Oil | Dual-fuel burners available |

| Furnace Design | Corrugated furnace + threaded smoke tubes | Three-pass wet-back |

| Burner Brand | Riello, Baltur, Weishaupt, Ecostar | Low-NOx imported options |

| Control System | PLC + Touch Screen (Siemens/Delta) | Full automatic with safety interlocks |

| Feed Water Temperature | 20°C – 105°C | With optional deaerator |

| Dimensions (approx.) | Varies (e.g., 3m – 8m length) | Compact horizontal layout |

| Weight (dry) | 5 tons – 50 tons | Depending on capacity |

| Emissions | NOx ≤ 30 mg/Nm³ (with FGR) | Compliant with strict environmental standards |

These parameters ensure optimal performance, energy savings, and compliance.

Here is a structural diagram of the WNS series three-pass design:

Design and Construction Standards

AIXBOILER WNS boilers are engineered to rigorous standards:

- Primary Standards: GB/T 16507 (China Water Tube Boiler Code), ASME Section I/IV (optional), PED 2014/68/EU, CE marking

- Materials: High-quality boiler steel (Q245R/Q345R), stainless steel tubes optional

- Welding & Inspection: Automated welding with 100% NDT (RT, UT) and hydrostatic testing

- Accessories: Economizer, air preheater, steam header, water treatment system

Advanced CFD optimization ensures uniform flow and minimal stress.

Applications

AIXBOILER WNS oil/gas fired steam boilers are widely applied in:

- Food and beverage processing (sterilization, cooking)

- Textile dyeing and finishing

- Chemical and pharmaceutical production

- Paper and packaging industries

- Hospitals and laundries

- District heating and power generation

They provide stable, high-quality steam for process and heating needs.

Quality Assurance and Testing

Every boiler undergoes:

- Hydrostatic test at 1.5 × working pressure

- Burner commissioning and efficiency testing

- Full NDT and third-party inspection (TUV, SGS, BV available)

- Performance validation with client FAT

Complete documentation ensures traceability and reliability.

Why Choose AIXBOILER?

With family-rooted expertise since 1978, government designation in 2025, and a team of over 60 senior engineers, AIXBOILER delivers innovative, eco-friendly WNS series boilers. We provide end-to-end services: custom design, manufacturing, professional installation, and 24/7 maintenance support for global clients.

Specifications

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

|---|---|---|---|---|---|---|---|---|---|

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.5 | 0.5 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 32.5 | 35.7 | 3.5 |

| WNS1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 64.5 | 70.1 | 5.5 |

| WNS2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 129.3 | 140.3 | 8 |

| WNS3 | 3 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 192.9 | 212.1 | 10.7 |

| WNS4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 258.2 | 283.4 | 11.6 |

| WNS6 | 6 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 388.6 | 424.2 | 17.5 |

| WNS8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 514.6 | 566.3 | 22.5 |

| WNS10 | 10 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 641.7 | 707.8 | 26.8 |

| WNS15 | 15 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 960.1 | 1061.7 | 35.2 |

| WNS20 | 20 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 1276.2 | 1415.8 | 45.5 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

- Ho