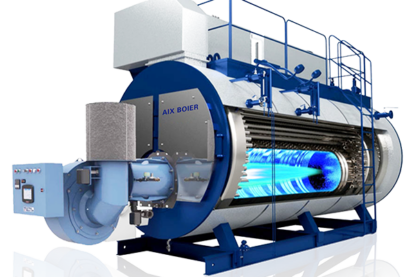

In 2023, AIX Boiler supplied a 3 TPH DZH manual chain grate biomass-fired steam boiler to a food processing factory in Lilongwe, Malawi. The client specializes in maize flour milling, peanut butter production, vegetable oil extraction, and snack manufacturing, requiring reliable, low-cost steam for cooking, sterilization, drying, and pasteurization.

Key Project Details

- Boiler Model: DZH3-1.25-AII (manual feeding chain grate) – 3 tons/hour steam capacity

- Rated Pressure: 1.25 MPa (saturated steam)

- Designed Fuel: Local Malawi biomass – wood chips, sawdust, maize cobs, peanut shells, and agricultural residues

- Efficiency: ≥82% (with basic economizer)

- Applications:

- Steam for maize cooking and conditioning

- Peanut roasting and oil pressing sterilization

- Vegetable drying and snack extrusion

- Hot water/steam for CIP cleaning and pasteurization

Why the Client Chose AIX Boiler

- Excellent fuel flexibility for abundant, low-cost local biomass with simple manual feeding

- Low initial cost and simple structure, ideal for small-scale food processors in Malawi

- Easy operation and maintenance with minimal skilled labor required

- Basic emission control (cyclone dust collector) to meet local environmental standards

- Full remote support, video training, and spare parts availability

Project Timeline

- Order confirmation: Q1 2023

- Manufacturing & testing: 70 days

- Sea freight to Beira port (Mozambique) + inland transport to Lilongwe: Q2 2023

- Installation & commissioning: Q3 2023

- Full commercial operation: August 2023

Client Outcome The boiler has dramatically reduced energy costs by using free/cheap biomass residues instead of diesel, provided stable steam for daily production, lowered carbon emissions, and supported a 15–20% increase in output. It serves as a successful example of sustainable biomass utilization in Malawi’s food industry.

For similar biomass steam projects in food processing, contact AIX Boiler: Email: [email protected] WhatsApp: +86 15188365066 / +86 13037600603 Website: https://www.aixboiler.com