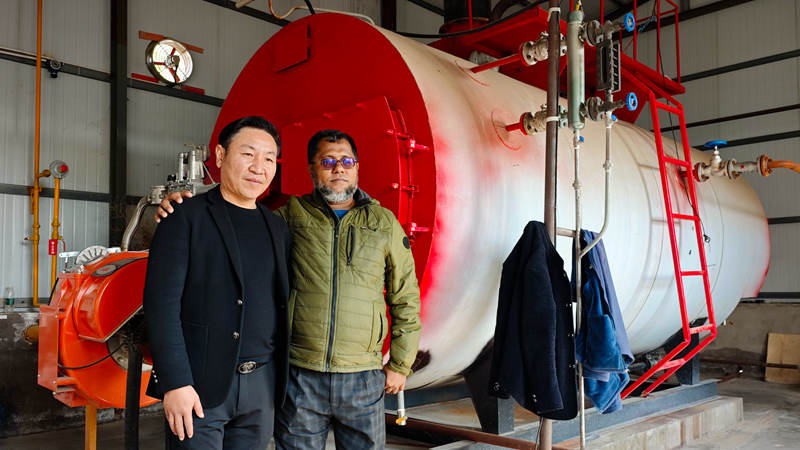

In 2018, AIX Boiler supplied a 5 TPH WNS series oil & gas fired steam boiler (1.25 MPa saturated steam) to a prominent textile weaving and dyeing mill located in Gazipur, Bangladesh. The client, a mid-sized fabric producer focused on cotton and blended yarn dyeing, printing, and finishing, sought to upgrade from an outdated coal-fired system to a cleaner, more efficient solution amid Bangladesh’s growing environmental regulations and rising coal costs.

Key Project Details

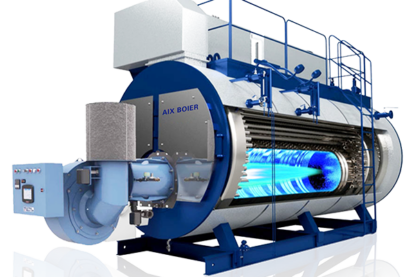

- Boiler Model: WNS5-1.25-Y(Q) – 5 tons/hour steam capacity

- Fuel: Dual-fuel design (natural gas as primary fuel, diesel as backup)

- Efficiency: ≥92% (equipped with economizer and low-NOx burner)

- Applications:

- High-temperature dyeing vats and jiggers (130–140°C)

- Mercerizing, scouring, bleaching, and desizing processes

- Stenter frames for heat-setting and fabric drying

- Provided consistent dry steam and stable pressure for 24/7 multi-shift production.

Why the Client Chose AIX Boiler

- Advanced low-NOx burner technology to comply with early Bangladesh emission standards

- Compact design and fast installation suited to limited factory space

- Comprehensive support including detailed engineering drawings, on-site commissioning, operator training, and reliable after-sales service

- Proven durability in humid, high-dust textile environments with A-grade quality certification

Project Timeline

- Order confirmation: Q2 2018

- Manufacturing & testing: 60 days at AIX Boiler factory

- Delivery to Chittagong port and inland transport: Q3 2018

- Installation & commissioning: Q4 2018

- Full commercial operation: December 2018

Client Outcome The boiler delivered immediate benefits: ~25% reduction in fuel costs (shift from coal to gas), improved steam quality for better fabric uniformity and reduced defects, near-zero downtime, and full compliance with local regulations. This project marked one of AIX Boiler’s early successful entries into Bangladesh’s booming textile sector.

For inquiries about similar oil & gas boiler projects in textiles, contact AIX Boiler: Email: [email protected] WhatsApp: +86 15188365066 / +86 13037600603 Website: https://www.aixboiler.com