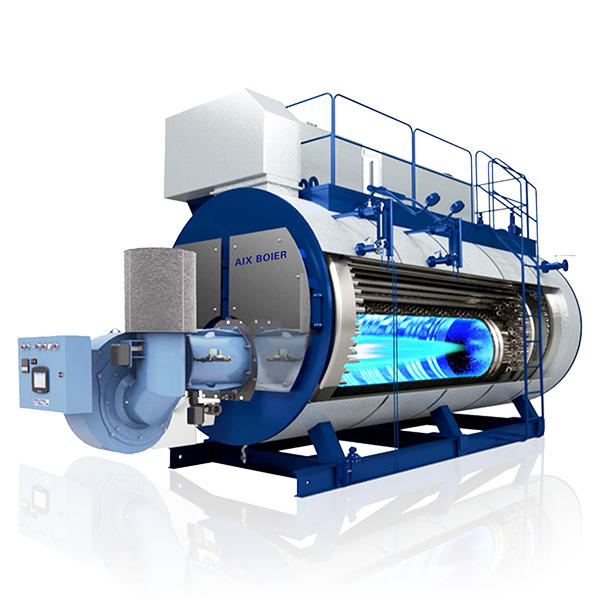

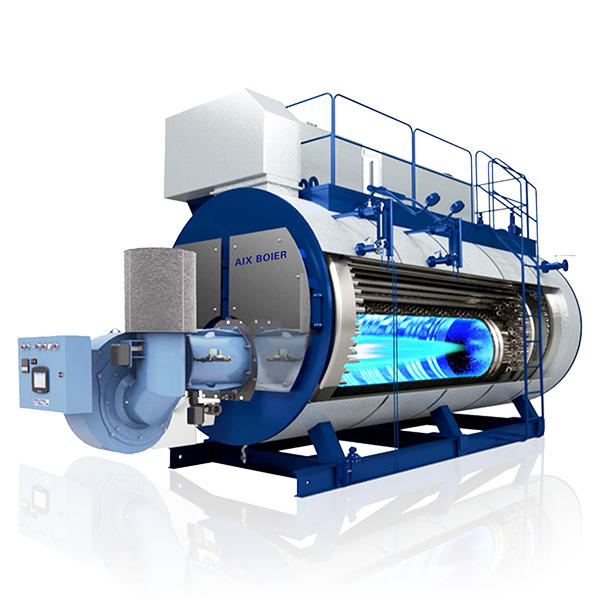

The WNS Series Condensing Oil/Gas Fired Steam Boiler, manufactured by AIX Boiler, a Chinese A-grade producer since 1976, is a horizontal, three-pass, fire-tube boiler that uses oil or gas to produce steam. Its integrated condenser recovers latent heat from exhaust gases, achieving thermal efficiency up to 98%. The fully automatic, compact design ensures easy operation, low maintenance, and low NOx emissions, meeting strict environmental standards. Ideal for industries like textiles, food processing, and chemicals, AIX’s WNS condensing boilers offer reliable, eco-friendly performance with significant fuel savings.

| Capacity | 2~25 t/h |

| Pressure | 0.7/1.0/1.25/1.6 MPa |

| Fuel | Heavy oil, diesel, natural gas, lpg, etc. |

| Application | Textile mill, brewery industry, rice mill, laundry, hotel, etc. |

| Brief Intro |

WNS series oil gas fired condensing boiler is a safe and high efficiency (98%) heating equipment with high automation, it is fast assemble boiler with flue gas three pass and wet back structure, widely used for industrial production. |

WNS condensing boiler is our patent technology, by using full wet back reverse chamber, the reverse chamber butt welded with the back tube head, more reliable. The combustion furnace by using the large diameter full corrugated furnace, large burning space to make the fuel burnt more efficiently. In order to improve the thermal efficiency, we equip economizer and condenser at the outlet of front smoke chamber.

1. Professional technology

Full wet back reverse chamber, butt welding for the reverse chamber and back dish head.

2. Large corrugated furnace

Boiler chamber by using large diameter corrugated furnace, large burning space to ensure fuel burnt more efficiently and large radiated heating area.

3. Sufficient output

Calculated by per ton steam generated by ≥ 25㎡ heating surface.

4. Multi-function safety explosion-proof equipment

There is explosion-proof equipment at the back of the boiler, it will release the high pressure in case of the fuel deflagration, and it will reset automatically. It also can be used for fire-watching sightglass and maintenance.

It can be widely used in the city gas transmission and distribution pipeline, oil, petrochemical industry refineries, chemical plants, metallurgical industry, power industry and other places that may produce gas leakage.

City Lifeline

City Lifeline

City Lifeline

City Lifeline

Steam Boiler

| Model |

Rated evaporation capacity (t/h) |

Rated steam pressure (Mpa) |

Thermal efficiency (%) |

Fuel consumption |

Overall dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) |

Overall Dimension Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

|

Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3 2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: