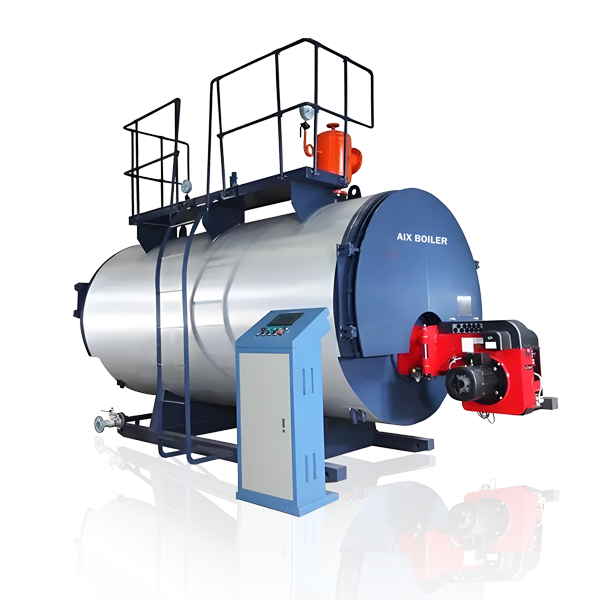

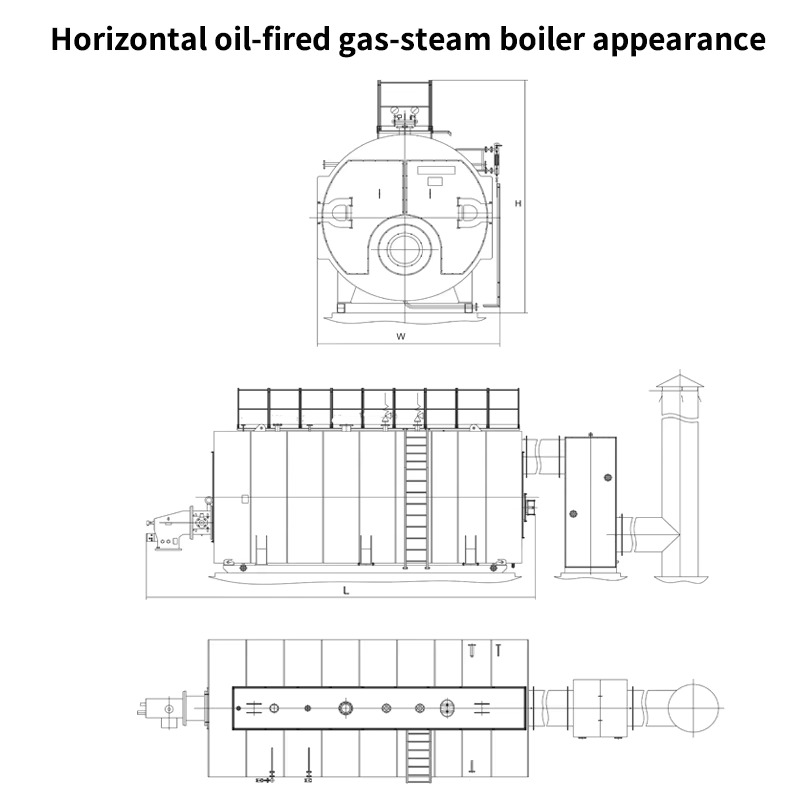

The WNS Series Oil/Gas Fired Steam Boiler is a horizontal, three-pass, wet-back fire-tube boiler that combusts oil or gas to produce steam for industrial applications. Manufactured by AIX Boiler, a Chinese A-grade producer since 1976, these boilers feature high thermal efficiency (up to 98%) with advanced burners, economizers, and corrugated furnaces, reducing fuel costs. Their compact, fully automatic design ensures easy installation, operation, and low NOx emissions, meeting environmental standards. Ideal for industries like textiles, food processing, and chemicals, AIX WNS boilers offer durability, safety with explosion-proof features, and low maintenance, making them a reliable, eco-friendly heating solution.

| Steam capacity | 0.5-20 ton/h |

| Pressure | 0.7-2.5Mpa |

| Available fuel | Natural Gas, LPG, Diesel, Heavy oil, Bunker Oil, Furnace Oil, etc |

| Rated thermal efficiency | 96% |

| Available industries | Food, beverage, feed mill, textile, paper, mill, refinery, chemical, pharmaceutical, laundry, etc |

WNS series 1ton/2ton/3ton/6ton/8ton/10ton/15ton/20ton steam boiler, low NOx emission, condensation integrated steam boiler is a kind of safe and high efficiency heating equipment with full automatic control system. This series oil gas fired boiler is horizontal type fast assembly fire tube boiler with structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet back structure, it can adapt to high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency.

• Energy saver, condenser and boiler structure can fully absorb the flue gas preheating and gasification latent heat,the thermal efficiency is 10% higher than the ordinary boiler.

• Adopt top level PLC automatic intelligent control cabinet and interlock protection program,which can effectively prevent water shortage, over pressure, over temperature, gas leakage, flame out and so on.

• Condenser adopts ND steel, which is characterized by its cost-effective,heat-resistant and corrosion-resistant performances.

• Condensing oil/gas fired boiler adopts horizontal flue gas three-pass integrated low resistance design with national invention patent technology, which facilitates a super high thermal efficiency, small floor area.

• Adopt corrugated furnace tank and threaded smoke pipe structure which not only increases the radiation and convection heat transfer area, but also satisfies the needs of the free expansion of high temperature radiation.

It can be widely used in the city gas transmission and distribution pipeline, oil, petrochemical industry refineries, chemical plants, metallurgical industry, power industry and other places that may produce gas leakage.

City Lifeline

City Lifeline

City Lifeline

City Lifeline

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

|---|---|---|---|---|---|---|---|---|---|

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.5 | 0.5 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 32.5 | 35.7 | 3.5 |

| WNS1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 64.5 | 70.1 | 5.5 |

| WNS2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 129.3 | 140.3 | 8 |

| WNS3 | 3 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 192.9 | 212.1 | 10.7 |

| WNS4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 258.2 | 283.4 | 11.6 |

| WNS6 | 6 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 388.6 | 424.2 | 17.5 |

| WNS8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 514.6 | 566.3 | 22.5 |

| WNS10 | 10 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 641.7 | 707.8 | 26.8 |

| WNS15 | 15 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 960.1 | 1061.7 | 35.2 |

| WNS20 | 20 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 1276.2 | 1415.8 | 45.5 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Electromagnetic steam generator is a new type of steam equipment that utilizes the principle of electromagnetic induction to convert electrical energy into thermal energy, thereby generating steam. This type of steam generator has the advantages of high efficiency, environmental protection, and energy saving, and has been widely used in industrial, medical, catering, and other fields.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: