The ultra-high temperature integrated superheated steam generator is an important thermal medium widely used in the industrial and energy fields. It continues to heat on the basis of saturated steam, causing the temperature to exceed the boiling point and form. The temperature of superheated steam can reach over 300 ℃, sometimes even as high as 600 ℃. This type of steam plays a crucial role in power generation, heating, and driving industrial equipment.

| Model | 808 |

| Target Gas | Natural gas ( CH4) and Carbon Monoxide |

| Working Environment | Humidity: <95%RH (No Condensation) |

| Gas Sampling | Natural diffusion |

Product Overview

The ultra-high temperature integrated superheated steam generator is an important thermal medium widely used in the industrial and energy fields. It continues to heat on the basis of saturated steam, causing the temperature to exceed the boiling point and form. The temperature of superheated steam can reach over 300 ℃, sometimes even as high as 600 ℃. This type of steam plays a crucial role in power generation, heating, and driving industrial equipment.

working principle

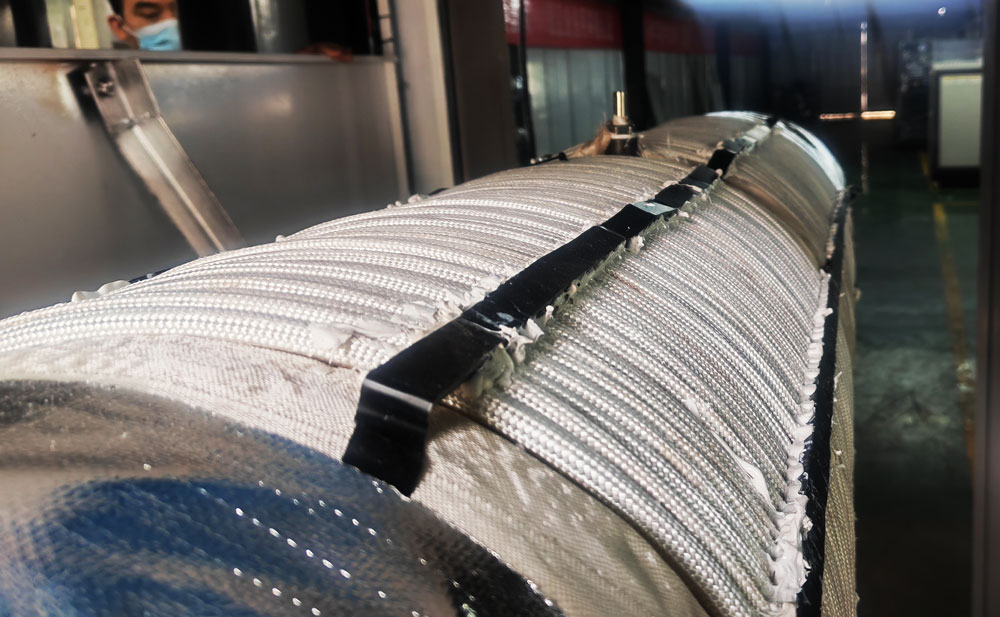

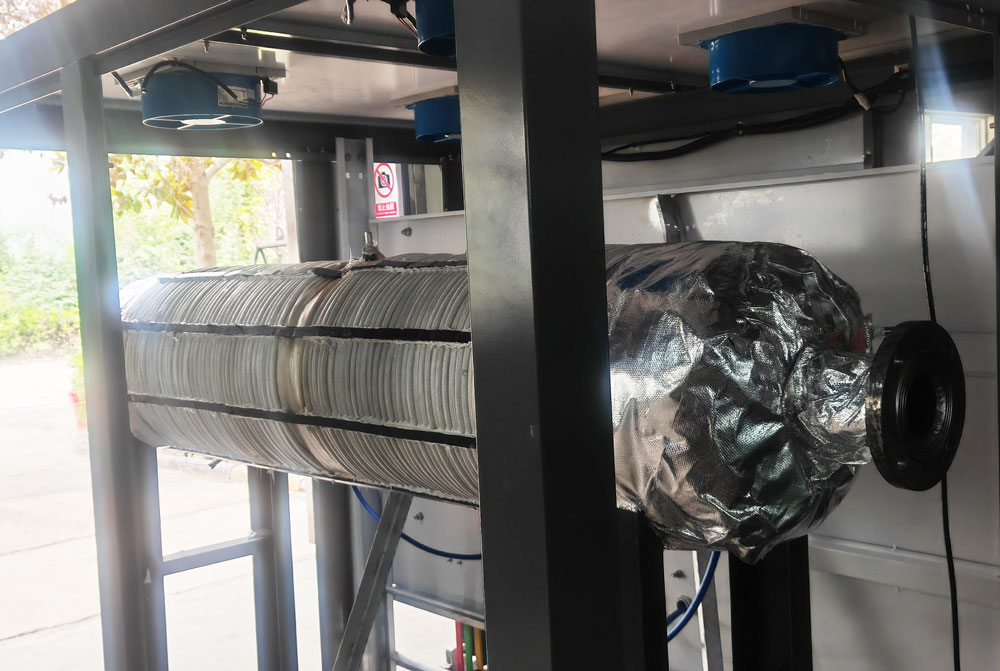

The working principle of the ultra-high temperature electromagnetic superheated steam generator is based on the principle of electromagnetic induction. Composed of a combination of resistance and electromagnetic heating technology, the front end is heated by a resistance heating tube to produce high-temperature saturated steam, and the rear end is heated by an electromagnetic induction heating element to perform secondary superheating on the saturated steam. The pressure, temperature, water supply, protection, and all control actions are uniformly monitored and processed by the CUP controller to produce high-temperature steam.

Product Features

The general steam generation devices on the market are high-temperature and high-pressure, making it difficult to achieve high temperature and low pressure. Our company has now overcome this technical challenge and successfully developed a low-pressure superheated steam generation device. The Aix electric heating steam generator equipment evaporates water at 100 ℃ to form saturated steam, which is then heated at high temperature to form superheated steam at 200-500 ℃. Superheated steam has the characteristics of high thermal conductivity, low oxygen concentration, and high heat capacity, and is widely used in fields such as drying processing, high-temperature testing, food processing, metal processing, and replacing thermal oil boilers

Product advantages

The ultra-high temperature steam equipment launched by Aix Electric Heating Institute has a wide range of applications, including food processing (heating, sterilization, degreasing, dehydration); Metal processing (metal quenching, degreasing and cleaning, electroplating and heating treatment); Environmental protection (solid waste drying, carbonization, harmless treatment, soil improvement, decomposition of dioxins and pesticide residues, fly ash deoxygenation treatment); Aix Electric Heating is a high-tech enterprise dedicated to the research and development, design, production, and application of efficient and energy-saving thermal energy technology. Our company is committed to becoming a leading electric heating technology application company in China, enabling our customers' products to stand on a higher technological platform while contributing to energy conservation and emission reduction. Independent research and development technology is the foundation of our company's foothold. At present, we have our own core technologies and have obtained national patents in the fields of electromagnetic heating, energy-saving renovation, and superheated steam applications. Electromagnetic heating steam superheater (patent number: ZL202321633300.4)

It can be widely used in the city gas transmission and distribution pipeline, oil, petrochemical industry refineries, chemical plants, metallurgical industry, power industry and other places that may produce gas leakage.

Food & Beverage Industry

Textile Industry

Rice Mill

Chemical Industry Boiler

Paper Processing Industry

Sugar Mill

Wood Processing Industry

Brewery Industry

Hospital School Hotel

Laundry

Pharmaceuticals Industry

Central Heating Boiler

| Model | 808 |

| Target Gas | Natural gas ( CH4) and Carbon Monoxide |

| Working Environment | Humidity: <95%RH (No Condensation) |

| Gas Sampling | Natural diffusion |

| Alarm | Human voice prompt and Siren alarm |

| Presetting Alarm Level | 7% LEL |

| CO: Following EN50291 | |

| Optional function | Gas cut-off Valve Relay output |

Electromagnetic steam generator is a new type of steam equipment that utilizes the principle of electromagnetic induction to convert electrical energy into thermal energy, thereby generating steam. This type of steam generator has the advantages of high efficiency, environmental protection, and energy saving, and has been widely used in industrial, medical, catering, and other fields.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: